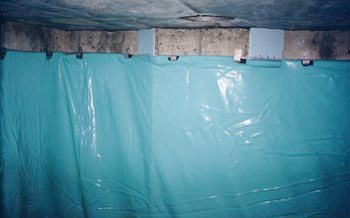

Installation of the Kentain closed top liner in a closed top tank requires a Kentain supervisor and or crew who are certified for confined space entry.

The prefabricated liner is taken through a manway and unfolded with the top side up. Semi rigid polyethylene tubing is inserted in the cross section hems.

Notches are provided at regular intervals to allow plastic rope to be fastened to the tubing.

A support frame is bolted to the ceiling of the concrete tank and the liner support lines are attached to the frame.

The liner is pulled up and secured in place thus fully suspending the liner inside the tank.

Where flanged fittings are located, the flexible flanged tubes are pulled through the openings and smoothed into place. The liner is then visually inspected upon completion of the installation.

Kentain flexible PVC liners are designed to make installation a simple, safe and efficient operation. Totally prefabricated at the factory, the Kentain liner can usually be installed in two to three days. Installation of the Kentain liner in horizontal tanks requires by a Kentain supervisor and /or crew who are certified for confined space entry.

Preparation of the interior of the tank does not require expensive downtime and sand blasting. Simply remove all sharp projections and loose scales on the existing tank interior.

The prefabricated flexible Kentain liner is lowered through the manway and spread out with the top side up. The manway flange is raised to the top of the tank.

An internal rib cage of plastic hoops and supports is installed and upon completion of the installation the liner is visually inspected by the Kentain supervisor.

Downtime is minimized since the tank walls do not have to be sand blasted.